What is Dry Ice Blasting?

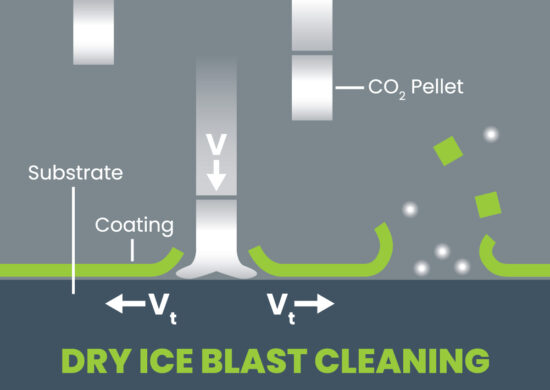

Dry ice blasting is a process where dry ice (solid CO2) pellets are accelerated in a pressurized air stream to clean or prepare a surface. Through sublimation, where CO2 instantly changes from a solid to a gas, the pellets create mini-explosions upon impact to effectively clean nearly any surface. Since it leaves behind no residue, dry ice blasting has become one of the most efficient and environmentally friendly methods to clean in an industrial or domestic environment.

Dry ice is non-conductive, chemically inert, non-poisonous and nonflammable. It has the ability to clean a wide variety of surfaces including production equipment, food processing equipment, printing presses, walls, windows, monuments and more. Dry ice can even be used on sensitive surfaces, such as electrical equipment and outdoor sculptures, without causing damage. An environmentally friendly cleaning process, it does not use any harmful chemicals and therefore does not generate any secondary waste. In a production environment, it is the ideal clean-in-place (CIP) cleaning solution that allows cleaning of machinery without time-consuming disassembly.

Solid CO2 pellets, also known as “blasting rice,” are readily available through dedicated dry ice distributors and at many industrial gas distributors. Besides the pellets, dry ice blasting also requires an air compressor that’s capable of supplying at least 100 PSI / 85 CFM+ (2.4 m3) of air. For best performance, the air should also be cool and dry. An aftercooler, such as Command Air® 500, is highly recommended for supplying cool, dry and filtered air for dry ice blasting.

WHAT EQUIPMENT IS REQUIRED FOR DRY ICE BLASTING?

Dry ice blasting requires a minimum of 85 CFM of air at 100 PSI, which must be supplied by a commercial grade or industrial air compressor (air requirements vary based on model). Most shop air compressors are sufficient as long as they meet this requirement and have at least a 1” air supply line, although the Commando® XP model may operate with air lines as small as 1/2”.

In addition to the air compressor, dry ice blasting also requires cool, dry air for best performance. An aftercooler such as the portable Command Air® 500, is highly recommended, especially in humid conditions or any environment where the air supplied from the compressor may contain moisture and does not have an integrated moisture filter.