WHY DRY ICE BLASTING?

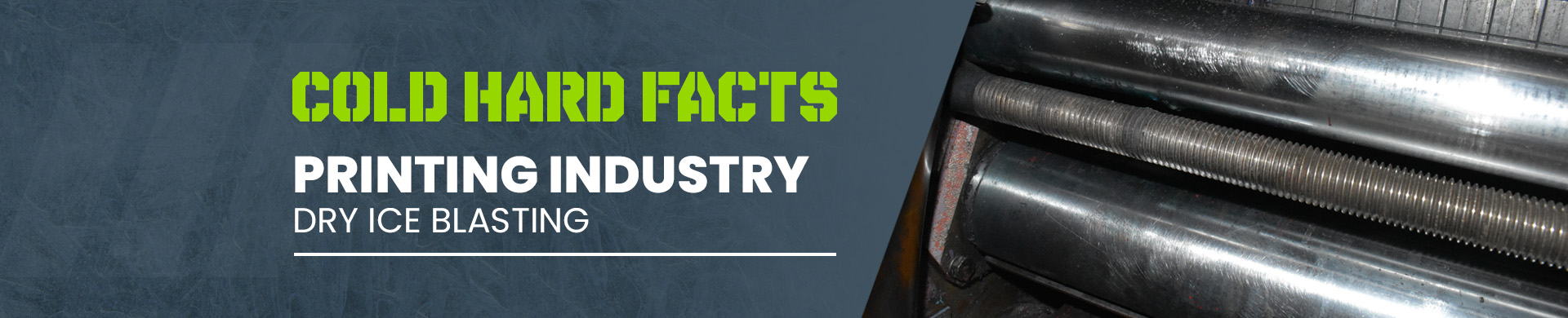

As a printing industry representative, it is inevitable to face the task of removing production residue. Similar to other kinds of media blasting, dry ice blasting uses a high-pressure air stream to clean the surface it is directed at. Made of reclaimed carbon dioxide, dry ice pellets are less abrasive and more efficient compared to other forms of media blasting.

When the pellets of CO2, also known as “blasting rice,” are propelled at high speeds, they sublimate immediately upon impact, transferring kinetic energy to the surface and cleaning any existing sludge or debris.

Since it leaves behind no residue, dry ice blasting has become one of the most efficient and environmentally friendly methods to clean an industrial or domestic environment. The unique composition of dry ice makes it an innovative solution for cleaning printing industry equipment.

BENEFITS OF DRY ICE BLASTING IN THE PRINTING INDUSTRY

It is believed that the U.S. Navy was the first to experiment with dry ice blasting as a tool to degrease metals and other materials in 1945. Similarly, a dry ice blaster will quickly remove burnished ink, heavy grease and stubborn caked-on paper residues typically found on industrial printing machinery. Dry ice blasting eliminates employee exposure to harmful chemicals and the risk of damage to any of the sensitive equipment.

Efficiency

Most equipment and machinery can be cleaned in place without any disassembly or cooling, reducing downtime in an industrial environment. An efficient cleaning process means machinery is back to production quicker, with minimal loss of revenue. Not only is dry ice blasting efficient, but it is also reliable. All Commando® dry ice blasting machines feature the BlitzFeed® patented freeze-less dry ice delivery system for superior pellet feeding. The design of this machine is engineered to prevent machine freeze-ups and ice blockages.

Safe

Dry ice blasting eliminates manual cleaning and exposure to unsafe conditions such as the toxic dyes and paints used in the printing industry. Long-term exposure to the harsh chemicals normally used to clean printing machinery can lead to respiratory problems and even cancers. Utilizing dry ice blasting as a cleaning measure ensures your employees are no longer at risk.

Although dry ice blasting is the safer alternative to manual cleaning, it is important to note that CO2 is increasingly toxic at concentrations above 1%. CO2 is heavier than oxygen and as a result, ventilation is required to be at or near ground level while dry ice blasting to ensure that the gas is removed from the area.

Environmentally Sustainable

Approved by the EPA, FDA, and USDA, dry ice blasting does not produce any secondary waste or additional pollutants that would otherwise end up in our waterways. Dry ice blasting does not require heavy cleanup; however, the waste products such as dislodged sludge can be swept up or vacuumed depending on the containment.

CO2 can also be recovered from other industrial processes and made into pellets used for dry ice blasting.

The printing industry in particular produces harmful toxins, making it the ideal candidate for dry ice blasting as its primary cleaning method.

WHY NU-ICE?

With 10+ years of experience, which extends to our assembly facility as well, Nu-Ice provides dry ice blasting for unrivaled cleaning power without harmful chemicals. After extensive research, design and testing, we developed a line of high-performance dry ice blasting machines for an environmentally friendly cleaning solution.

The Commando® line of dry ice blasters is ideal for various applications, and dry ice is the preferred cleaning method for food processing equipment, chemical machinery, printing instruments, welding cells, fire restoration, historical restoration, power generation equipment and more. Using only standard dry ice pellets, Commando® dry ice blasting machines easily remove production residue, grease, oils, tar, mold and other materials.

As a family and veteran-owned company based in Jackson, Michigan, we’re proud to say all of our dry ice blasting machines and accessories are proudly Made in the USA.